Consolidate cutting-edge expertise and precise programming

Youxing Shark 4.0 Smart Factory combines research and development innovation with smart production. Integrating 4C technologies such as computer, communication, display, and control, leading the forefront of technology, ensuring efficient and stable product quality, is an epoch-making leap in the field of adhesives in China.

Yearly pre-production

aseptic tube

Weight sensors

control valve

automatic control point

temperature sensor

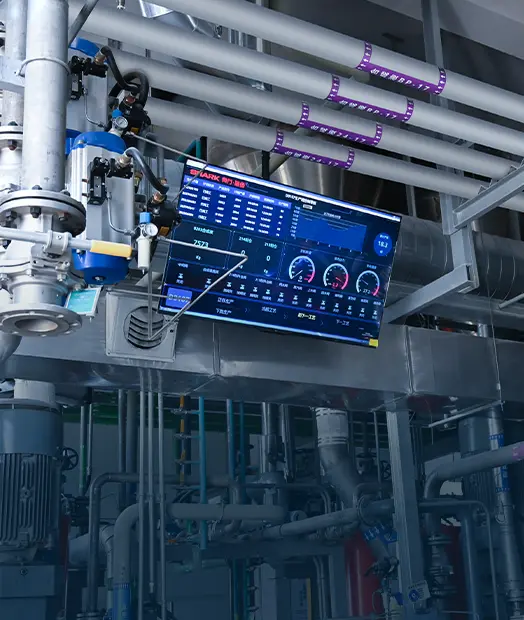

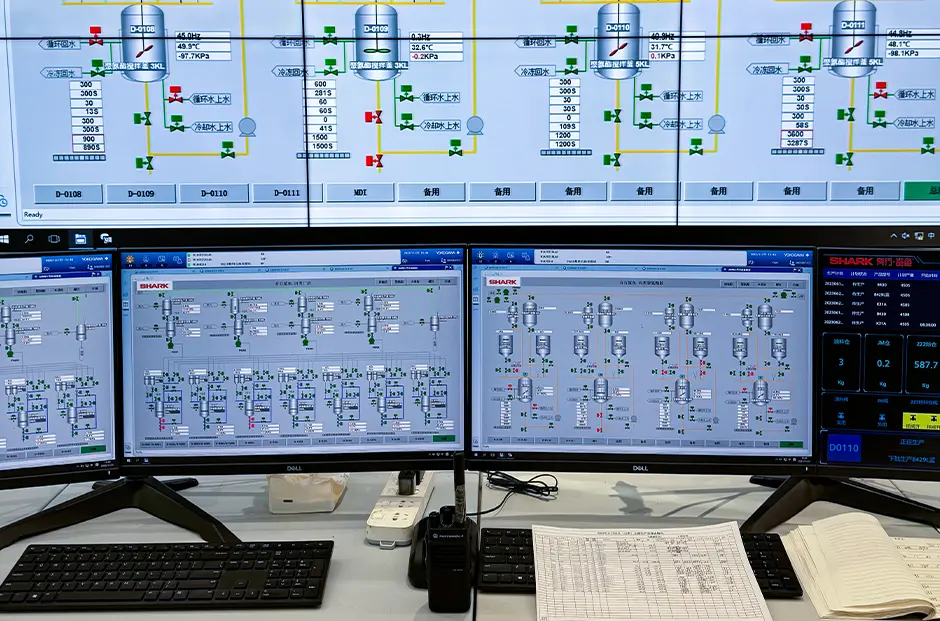

Yokogawa DCS System

Industry 4.0 Top Distributed DCS Control System

More than 13,000 automatic control points

More than 1800 control valves

Fully enclosed intelligent feeding system

No one intervenes in the whole process, anti-bacterial and quality preservation without contamination

More than 20,000 meters of sterile piping

More than 1800 Taiwan Iron King valves

Siemens MCS Production Collaboration System

Realization of man-machine interoperability, digital management, precise control of quantity

Three-tenths of a millimeter precise feeding

More than 150 weight sensors

E+H Temperature Sensors + YORA Refrigeration Systems (USA)

Precise temperature control for fine quality

Temperature error control within 1 degree

More than 30 temperature sensors

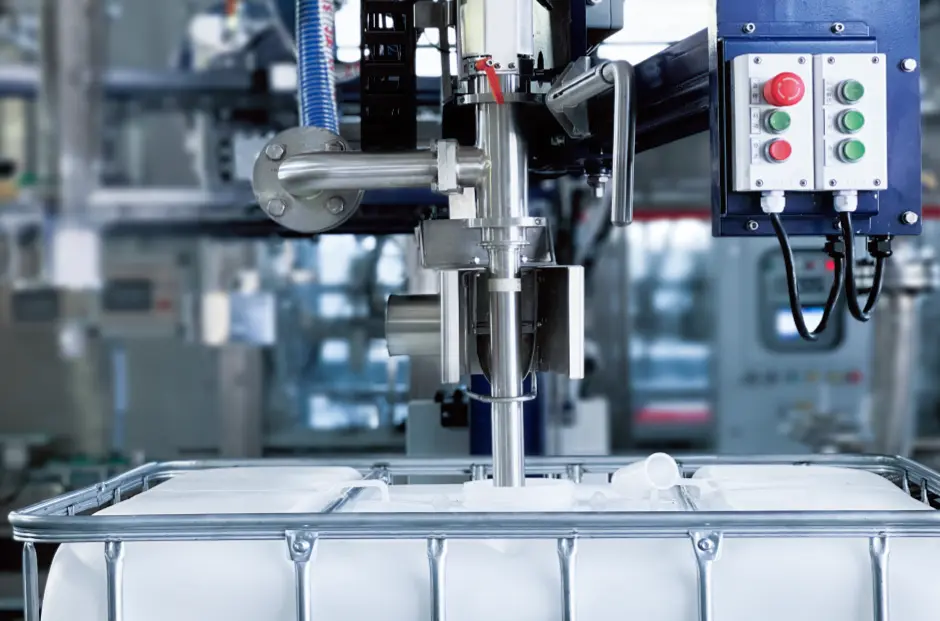

METTLER TOLEDO Complete Automated Filling Systems

Automatic weighing, automatic capping, automatic labeling, automatic palletizing

10 automatic filling systems

More than 500 feedback control points

METTLER TOLEDO transmission lines

Real-time feedback, zero error and zero mistake

10 automatic labeling machines

More than 40 duplicate weighing modules