2023-12-18

technical background

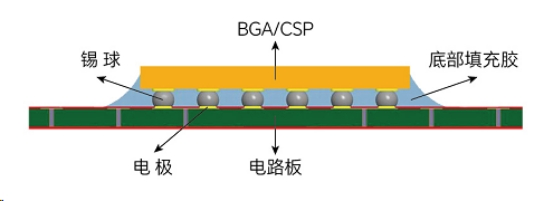

Underfill, also called underfill, has the functions of reducing the stress impact caused by the difference in thermal expansion coefficient between the chip and the substrate, improving the reliability of the component structural strength, and enhancing the drop resistance between the chip and PCBA. It is mainly used in the PCB board-level packaging process of terminal products such as mobile phones, computers, and tablets. It is a key packaging material to improve the reliability of electronic products. The underfill rubber market basically relies on imports, and there is currently a large gap in the country.

Performance requirements

Low viscosity, good fluidity, high filling efficiency

Low CTE, high Tg, low modulus, high reliability

Reworkable and easy to clean

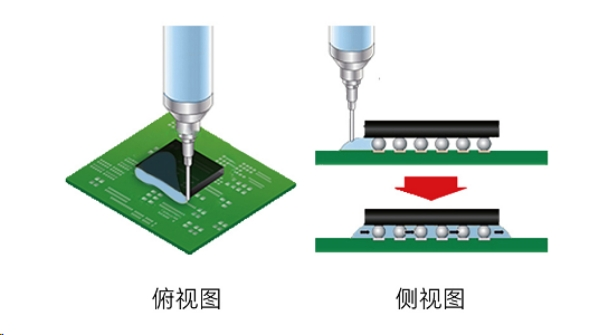

Underfill technology process:

Use capillary action to quickly flow the adhesive through the bottom of the BGA chip Bottom of the chip

Dispensing method: "1" type or "L" type

Focus on performance: liquidity

The performance of underfill glue products directly affects the yield of integrated circuit board-level chip packaging, so the early operations must be filled in place perfectly. To ensure rapid and complete filling, the adhesive must have low viscosity and fast flow, which is also the first consideration when choosing a bottom adhesive.

Youxingsha—Board-level underfill glue SHARK 1162 for the electronics industry

Working on "core" technology, efficient and stable

SHARK 1162 is a board-level underfill adhesive for the electronics industry launched by Youxingshark. It is a one-component heat-cured epoxy adhesive. It is a low-halogen environmentally friendly product. It has good fluidity at room temperature and can be cured at medium temperatures. It has Excellent electrical properties, excellent performance in actual industrial applications.

Features

Low viscosity, good flow properties, low CTE, high Tg, low modulus

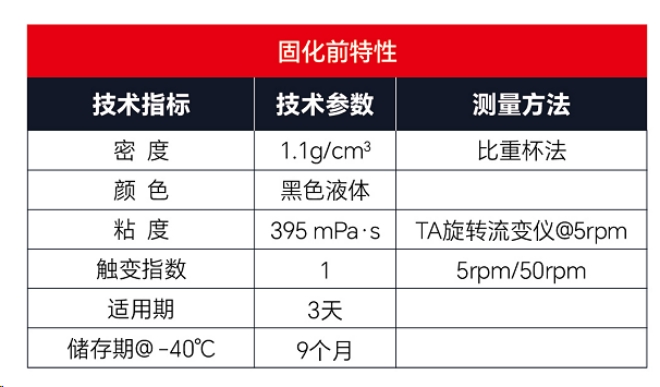

Technical Parameters

Characteristics before curing

Typical Cure Properties

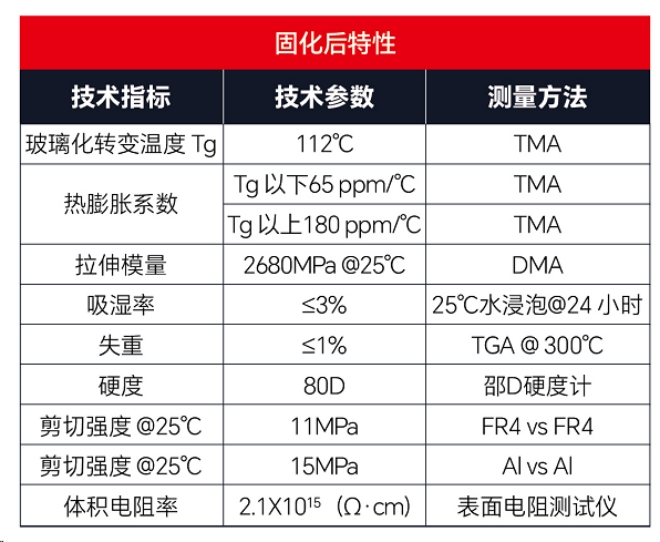

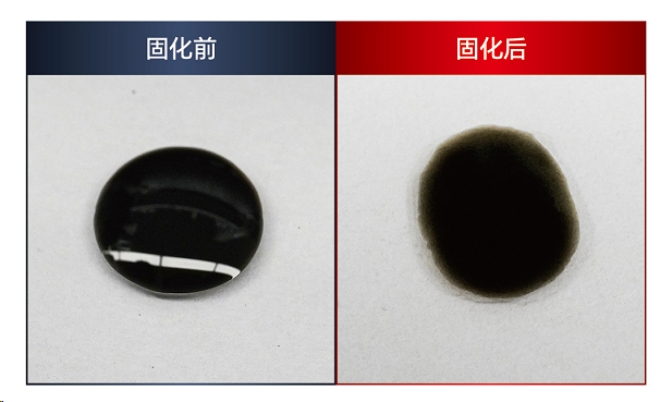

Recommended curing conditions: 10 min @ 130°C (can be adjusted appropriately according to customer curing equipment and oven temperature)

Curing thermal weight loss: < 1%

Cured properties

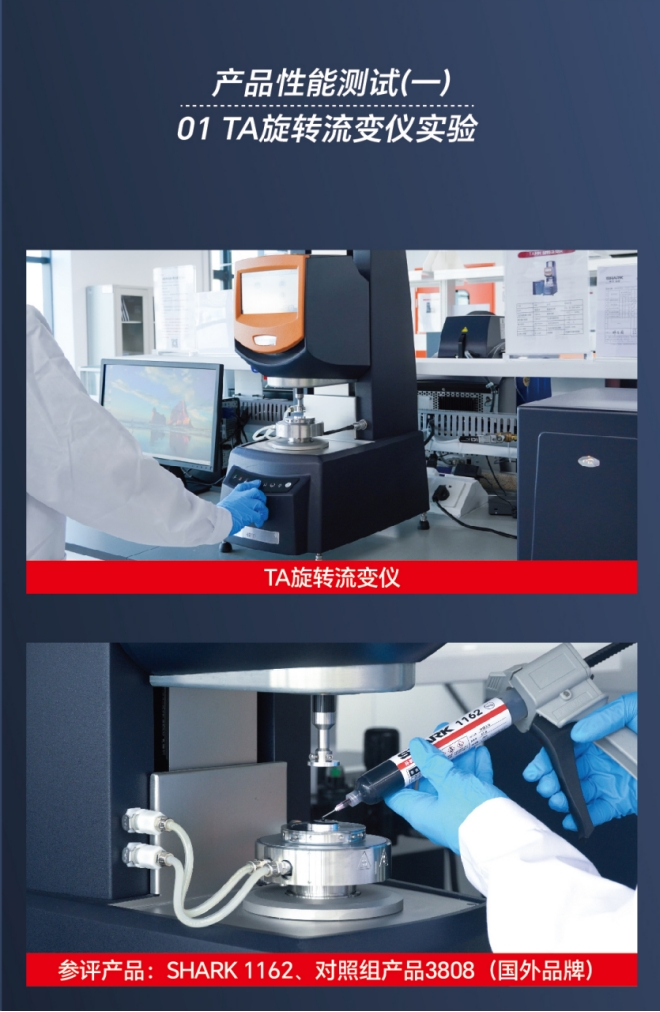

Product performance evaluation (1): Liquid rheological properties

01 TA rotational rheometer experiment

Experimental results

The rheological curves of SHARK-1162 and the control product 3808 (foreign brand) basically overlap, and the viscosities are both ≤500mPa·s.

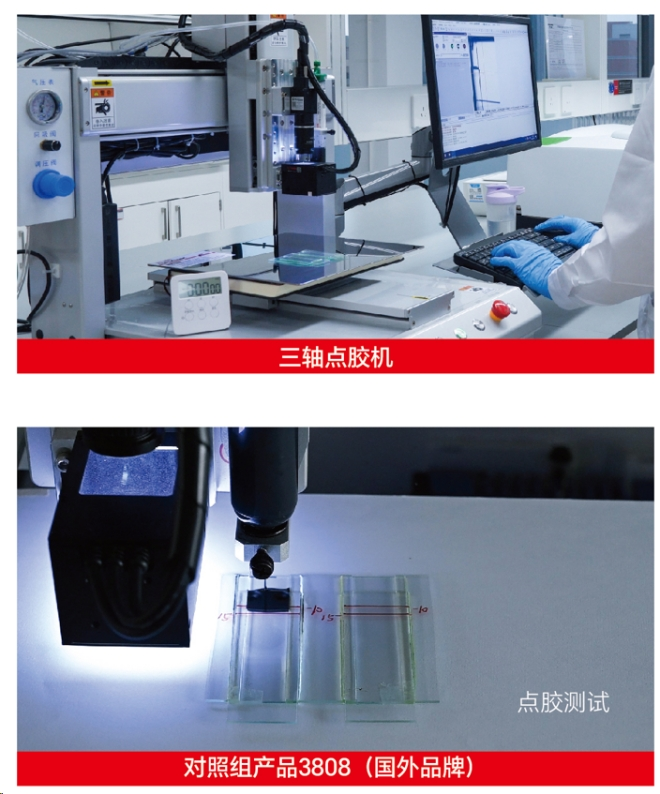

02 Actual measurement of dispensing application

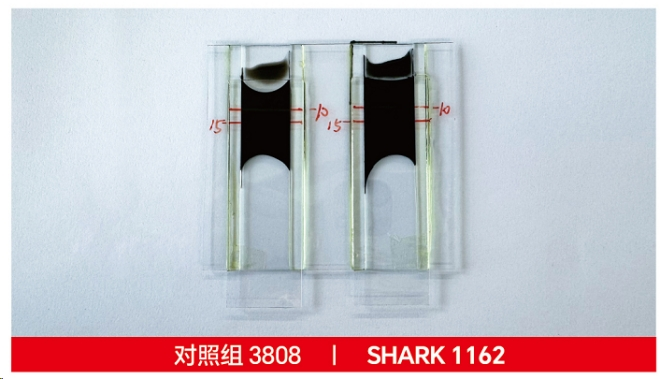

Compare the fluidity through the time it takes for the two adhesives to flow through the gauge lengths of 10mm and 15mm.

Experimental results

After standing for 5 minutes, the flow patterns of the two adhesives were similar.

Summarize

The viscosity and fluidity of SHARK-1162 are comparable to foreign products, showing excellent fluidity and filling effects.