2023-12-18

Underfill is used in the underfill process of Chip Scale Package (CSP) or Ball Array Package (BGA). It can effectively reduce the overall temperature expansion coefficient mismatch between the chip and the substrate or the impact caused by external forces. Improve product durability and reduce the possibility of failure.

Focus on performance: reworkability

Underfill is often required to be reworkable. Since the value of the printed circuit board (PCB) is high, if the chip is found to be defective, the chip must be repaired. Reworkability allows the underfill to be removed for reuse of the PCB, saving costs.

Youxingsha—Board-level underfill glue SHARK 1162 for the electronics industry

Easy to repair as the "core" wants

SHARK 1162 is a board-level underfill adhesive for the electronics industry launched by Youxingshark. It is mainly used for filling BGA and CSP chip solder joints. It is a one-component heat-cured epoxy adhesive and is a low-halogen environmentally friendly product. This product has good filling properties, reliability and reworkability, and has excellent performance in actual industrial applications.

Features and advantages

Low viscosity, good flow performance, low CTE, high Tg, low modulus, can be repaired and cleaned

Technical Parameters

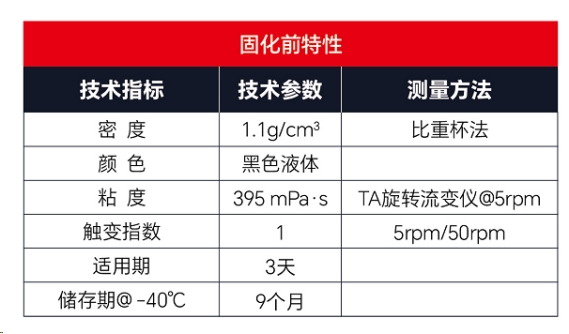

Characteristics before curing

Typical Cure Properties

Recommended curing conditions: 10 min @ 130°C (can be adjusted appropriately according to customer curing equipment and oven temperature)

Curing thermal weight loss: < 1%

Cured properties

SHARK1162 is reworkable and easy to clean. After the colloid is heated to a specific temperature and used with professional tools, it can be cleaned efficiently without damaging the pad, improving the rework yield rate.

Product performance display (3): repair operation

Due to the chemical properties of epoxy resin, SHARK 1162 exhibits glassy properties after heat curing, with high body strength and bonding strength. Improper repair can easily cause the pad to fall off, deform the PCB, or damage the BGA. In order to better utilize the advantages of SHARK1162, this issue will share the correct repair steps of SHARK1162.

Tools and materials preparation

Tools: heat gun, soldering iron, rework bench, scraper

Materials: flux, soldering tape

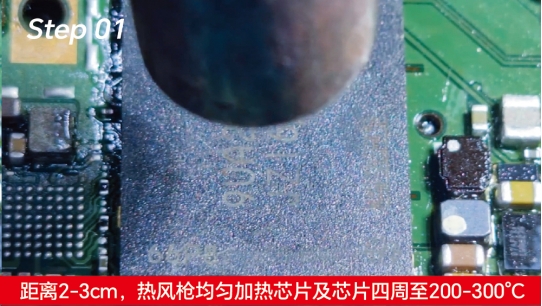

1. At a distance of 2-3cm, use a hot air gun to evenly heat the chip and its surroundings to 200-300°C.

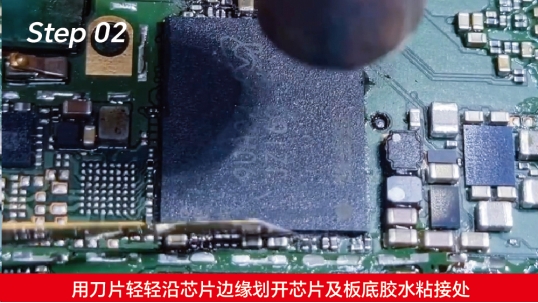

2. Use a blade to gently cut the glue joint between the chip and the bottom of the board along the edge of the chip.

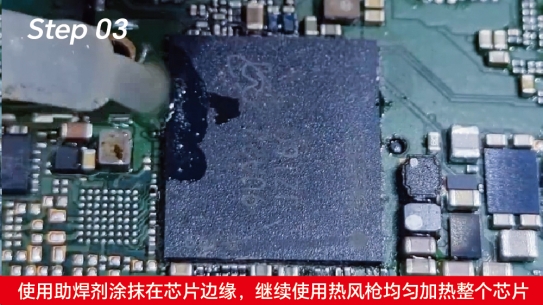

3. Apply flux to the edge of the chip, and continue to use the hot air gun to evenly heat the entire chip.

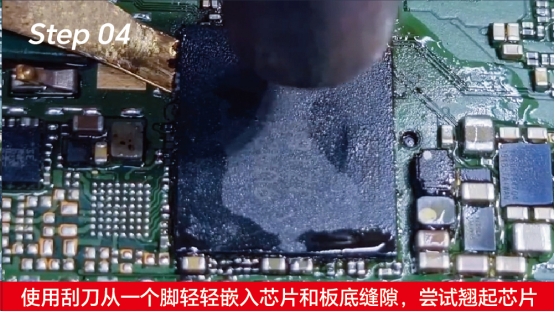

4. Use a scraper to gently insert one foot into the gap between the chip and the bottom of the board, and try to lift the chip.

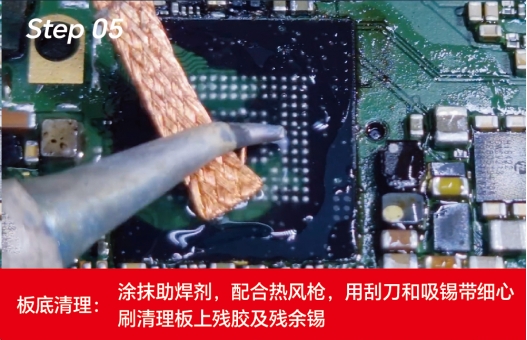

5. Cleaning the bottom of the board: Apply flux, use a hot air gun, and use a scraper and a desoldering tape to carefully clean the residual glue and tin on the board.

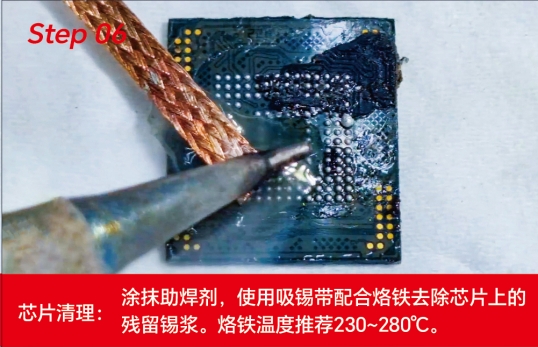

6. Chip cleaning: Apply flux and use a soldering tape and a soldering iron to remove the residual solder paste on the chip. The recommended soldering iron temperature is 230~280℃.

Precautions for repair

1. Chip-level maintenance requires professionals

2. Heating temperature and maintenance time vary depending on chip size and solder paste type.